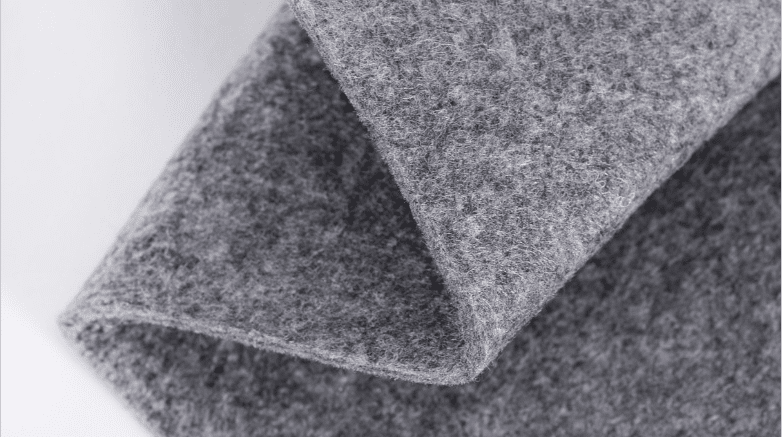

Hi everyone, I’m Li, an automotive interior materials enthusiast. Today, let’s talk about the use of needle-punched non-woven fabric in car interiors. Many of you might be familiar with this material, but what are its actual pros and cons? Let’s dive in and find out.

Advantages of Needle-Punched Non-Woven Fabric

1. Lightweight and Strong

Needle-punched non-woven fabric is incredibly lightweight yet boasts high strength and durability. This is crucial for car interior materials as it helps reduce the vehicle’s weight, improving fuel efficiency, while ensuring long-lasting interior components.

2. Sound Absorption and Noise Reduction

This fabric excels at absorbing sound and reducing noise. When used for car carpets, door panels, and other interiors, it can significantly lower the noise generated during driving, enhancing the comfort of the ride.

3. Eco-Friendly and Recyclable

Many needle-punched non-woven fabrics are made from recycled materials, making them environmentally friendly. Moreover, they can be recycled at the end of their life cycle, aligning well with the automotive industry’s push for sustainable materials.

4. Versatile Crafting and Design

This fabric can undergo various surface treatments and dyeing processes, offering great design flexibility. Whether you aim for a luxurious interior or a simple, practical one, different treatments can help achieve the desired style.

5. Cost-Effective

Compared to other high-end interior materials, needle-punched non-woven fabric is relatively inexpensive, making it a popular choice for economical and mid-range vehicles.

Disadvantages of Needle-Punched Non-Woven Fabric

1. Moderate Durability

While strong, needle-punched non-woven fabric isn’t as durable as some high-end materials like genuine leather or Alcantara. Over time, it may show signs of wear and tear.

2. Less Luxurious Feel

The texture of needle-punched non-woven fabric is decent but falls short compared to premium leather or textile fabrics. For those who seek an ultra-luxurious feel in their high-end vehicles, this might not be ideal.

3. Complex Cleaning and Maintenance

Cleaning and maintaining needle-punched non-woven fabric can be a bit challenging, especially when dealing with stubborn stains. This could be a hassle for car owners who use their vehicles frequently.

4. Poor Breathability

The breathability of needle-punched non-woven fabric is relatively poor. In hot summers, this can lead to higher temperatures in seats and interiors, affecting comfort.

Conclusion

In conclusion, needle-punched non-woven fabric presents clear advantages, particularly in terms of weight reduction, environmental friendliness, and cost. These benefits make it a popular choice for mid to lower-end vehicles. However, its drawbacks in durability, texture, and maintenance complexity need to be considered.

If you prioritize practicality and cost-effectiveness, needle-punched non-woven fabric is definitely worth considering. But if you seek luxury and durability, you might want to explore other high-end materials.

I hope this post helps you better understand the pros and cons of using needle-punched non-woven fabric for car interiors. Feel free to share your thoughts and experiences in the comments below!