Our factory founded in 1993, as non woven spunlace fabric manufacturer supplier wholesaler (hydroentangled nonwoven fabric), developing new materials, vigorously developing renewable resources, improving process energy efficiency, promoting degradable materials, and implementing ESG sustainable programs in many industries, ESG (Environment, Society, Governance) sustainability program is a series of sustainable development strategies and measures formulated and implemented by us in its long-term operation, taking into account the three dimensions of environmental protection, social responsibility, and corporate governance.

History of our non woven spunlace fabric manufacturer

Obtained ISO:9001 certification in 2005.

Got TS16949 certification and became a second-tier supplier for FAW Volkswagen and Audi in 2015.

Supporting medical auxiliary materials head enterprise Zhende medical, supporting tourism biodegradable products, become the designated supplier of Huazhu Group in 2022.

Qualifications of our non woven spunlace fabric manufacturer

Qualifications of our non woven spunlace fabric manufacturer. High quality, meets many international standards, exported to more than 40 countries around the world. Support customization, labeling, finished product production.

What is non woven spunlace fabric

Spunlace non woven fabric, is a kind of high-pressure micro-fine water jet to the microfiber nonwoven fabric layer or multi-layer fiber network, let the fiber entangled with each other, so that the fiber network can be strengthened and has the strength of the spunlace nonwoven fabrics, the fabrics obtained after the reinforcement of the spunlace nonwoven fabrics.

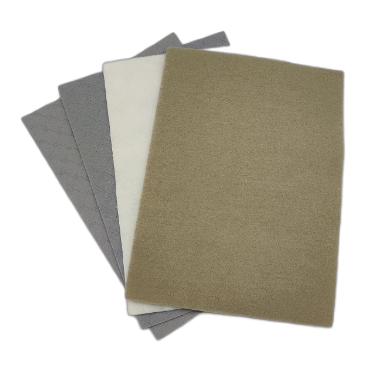

General spunlace fiber material origin is very wide, can use polyester, polyamide, polypropylene, viscose fiber, chitin fiber, microfiber, Tencel, silk, bamboo fiber, wood pulp fiber, seaweed fiber and other materials.

Material introduction of non woven spunlace fabric

Raw material 1: RPET, RPP and other recycled fibers.

Process: Nonwoven fabrics made through needle punching, spunlace and other physical processing.

Performance: Recycling of materials, substantial reduction of carbon emissions

Raw material 2: viscose, cotton, hemp, acetic acid, lyocell, modal and other plant-based fibers

Process: Nonwoven fabrics made through physical processing such as needle punching and hydroentanglement.

Performance: can be decomposed in a certain environment, reducing waste.

Raw material 3: mugwort, PLA, far-infrared, microcapsules and other special functional fibers.

Process: Nonwoven fabrics made by needle punching, hydroentanglement(spunlace) and other physical processing.

Performance: biodegradable and at the same time gives the effect of odor purification, anti-bacteria, health and wellness, etc.

Non woven spunlace fabric uses

Non woven spunlace fabric ( hydroentangled nonwoven fabrics) are suitable for use in the medical field, industrial field, and can also be used to manufacture clothing and construction materials. It can also be used in the home to make all kinds of daily necessities.

(1) Medical, health nonwoven fabrics: surgical gowns, protective clothing, disinfection cloth, medical curtains, trauma dressings, masks, diapers, civilian wipes;

(2)Sanitary cloths: wet face towel, magic towel, airlaid napkin,linen like napkin,cosmetic cotton pads, soft towel, beauty products, sanitary napkins, sanitary pads and disposable sanitary cloths;

(3) Nonwoven fabrics for home decoration: wallpaper, tablecloths, bed sheets, bedspreads, etc;

(4) Nonwoven fabrics for garments: lining, bonded lining, wadding, shaping cotton, various synthetic leather backing, etc;

(5) Nonwoven fabrics for industrial use; filtering materials, insulating materials, coated base fabrics, cement packing bags, geotextiles, wrapping cloths, etc;

(6) Agricultural nonwoven fabrics: crop protection fabrics, seedling fabrics, irrigation fabrics, thermal curtains, etc;

(7) Other nonwoven fabrics: high-grade rags for electronic occupations, high-grade rags for instruments and meters, aviation rags, space cotton, heat insulation and soundproof materials, grease-absorbing felts, cigarette filters, bag and bag tea bags, etc.

Translated with DeepL.com (free version)

Non woven spunlace fabric specificities

1. Hydroentangled nonwoven fabrics are punctured with water to make fibers flexibly entangled together, so that there is always no damage to the fiber, so it does not affect the softness of the fiber specific. So it is both strong and soft.

2. The appearance looks very close to traditional textiles. Unlike fabrics made of other non-woven materials, it looks more natural and soft.

3. Because the strength of hydroentangled nonwoven fabric is very high, it is abrasion-resistant and tensile strength, and it is not easy to lint. It will not add any adhesive in the manufacture, its toughness depends on the fiber, will not be washed more and more weak.

4. It has strong moisture absorption ability, and can quickly absorb moisture into the fiber network. Breathability is also very good, able to manufacture clothes without bringing stuffiness.

5. The appearance of spunlace nonwoven fabric is rich in design and can change many tricks to satisfy various aesthetic demands.

6. The production process is long, covers a large area, complex equipment, high water quality requirements and high energy consumption.